Introducing Zuma and Ojai – Pedal Power Supplies

EDIT: Zuma and Ojai available now! Buy Zuma ($249) | Buy Ojai ($149) We hope 2016 has been great for you so far. It’s been

Free US Shipping On Orders Over $49

Easy 30-Day Returns

Financing Available Through ![]()

When we set out to design a line of effects pedal power supplies, we had one overarching goal in mind: to make sure you never have to worry about power again. Zuma and Ojai are the highest horsepower, most technologically advanced effects pedal power supplies of their kind. Each individually isolated, ultra-low-noise output provides a staggering 500mA of current. Dual-stage topology, pre-regulated outputs, optically isolated feedback, and advanced multistage filtering ensure your pedals will achieve their highest possible dynamic range.

Our power design team of Gregg Stock and Josh Forbes have many years of experience in power system design, from developing mission-critical power systems for the aerospace industry, to developing best-in-class power supplies for top-selling power amplifiers, studio monitors, guitar amplifiers, and more. We’re using this vast experience to provide clean, dependable power to all of your effects pedals.

So how does all of this power stuff actually work? How did we design a switching power supply that is actually quieter than a linear power supply? How did we manage to make our supplies so energy-efficient? How is it possible that 500mA of current are available on every output? Take a step into the Strymon engineering labs where analog engineer Josh Forbes will tell you all about how this was achieved.

Designing power supplies for guitar pedals has traditionally been a trade-off between noise performance and energy efficiency. Bulky, inefficient Linear Power Supplies were used for noise-sensitive applications and noisy Switched-Mode Power Supplies (SMPS) were used for compact, energy efficient designs. This article explores these two power supply technologies and how we designed a family of power supplies with the noise performance of linear supplies and the efficiency of SMPS.

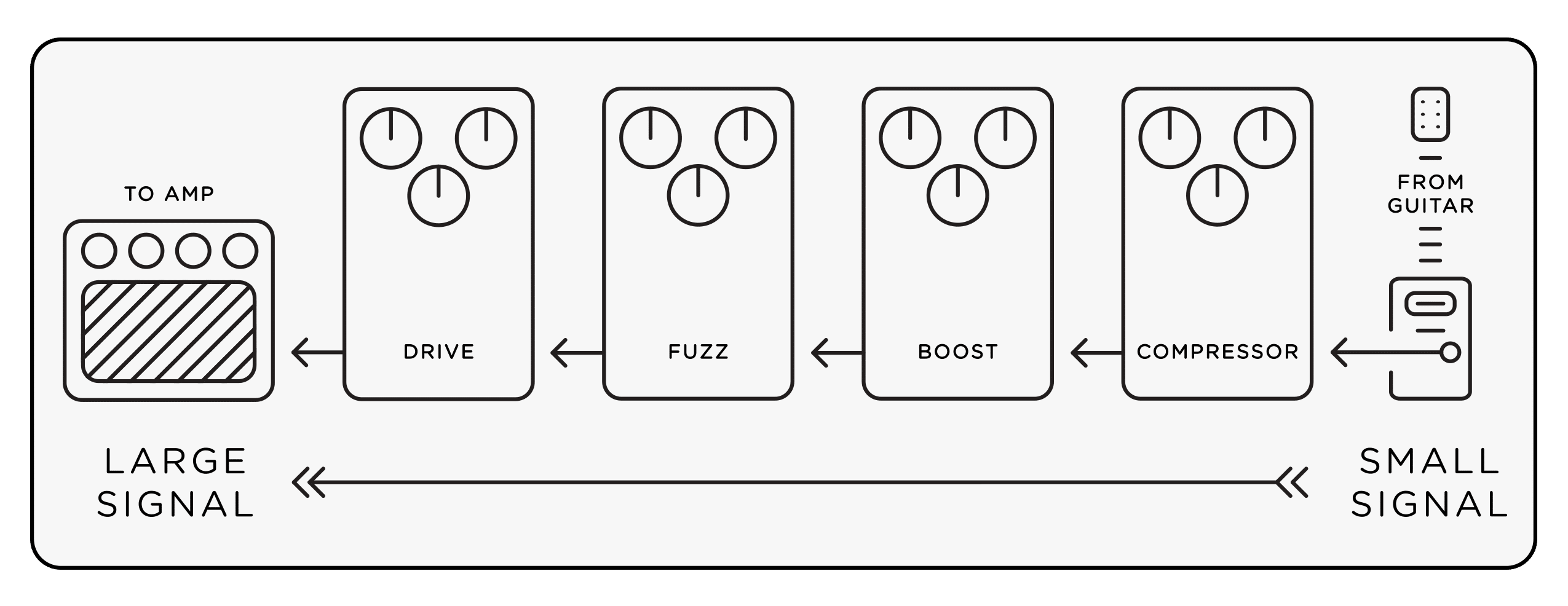

An electric guitar produces a very weak electric signal. Guitar amplifiers, as well as guitar pedals such as distortion pedals, fuzz boxes, and compressors, apply gain to shape this signal and convert it into audible sound.

Figure 1

Figure 1

These gain stages also amplify unwanted electrical noise. This noise limits dynamic range by washing out intended signals that are quieter than the amplified noise. To prevent power supply induced noise, guitar pedals have historically been paired with low-noise linear supplies or batteries. Many modern guitar pedals are still designed to rely on low-noise supplies for quiet operation.

Linear Power Supplies and Efficiency

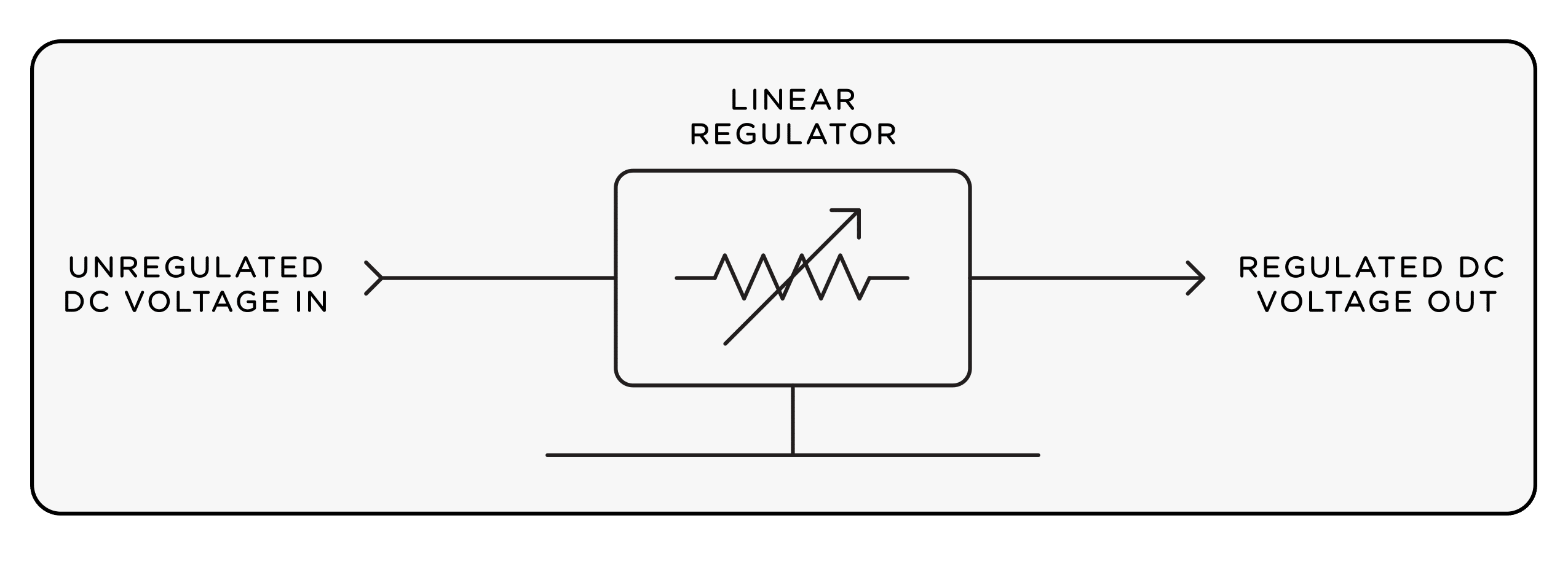

A linear regulator employs active circuitry that acts as an adjustable resistor between the input and output stage. The resistance of this element is varied to maintain a regulated output voltage.

Figure 2

Figure 2

In the process, the element dissipates power equal to the current through it multiplied by the voltage across it (P = I*V). This dissipation severely limits the efficiency of linear power supplies. Taking into account the other power losses in a linear regulator (like losses in the transformer, rectifier, etc.), the overall efficiency is typically under 50%.

Using a supply that is less than 50% efficient means that for every watt delivered to your guitar pedals, more than a watt is wasted in the linear power supply. Because of this inefficiency, many regions of the world have outlawed the sale of external linear power supplies in favor of efficient Switched-Mode Power Supplies.

Linear Supplies and Heat

The energy wasted in inefficient power supplies is converted to heat. For instance, if a 50% efficient supply delivers 20W of power to a pedal board, there will also be 20W of power dissipated as heat in the power supply. Every second, each watt of power dissipated contributes one joule of heat that will need to find a path from the supply to the ambient environment. If not properly dealt with, this heat will cause various problems. It can damage components by raising their temperatures above rated limits, render the supply too hot to safely handle, force the supply to temporarily turn off, etc.

To prevent temperature related problems, linear power supplies require bulky heatsinking and/or fans to transfer heat to the ambient environment. If operated in an enclosed space, these mitigation techniques will become ineffective as the heat increases the temperature of the ambient environment. Additionally, fans fail and tend to be noisy and get noisier with age.

Linear Supplies and Travel

The balance between maintaining regulation and avoiding excessive internal power dissipation means that linear power supplies will only operate over a limited input voltage range, rendering them only usable in specific regions. These regions include:

Consider a US power supply optimized to regulate so long as the input voltage does not sag below 15% of nominal (15% is a responsible margin to minimize power loss while ensuring regulation). If we operated this supply in Japan, it would be driven by 100VAC, more than 15% below 120VAC. As a result, the supply would be out of regulation and the voltage ripple on the input would propagate to the output of the regulator. This noise would likely find its way into the audio path of the guitar pedal it is powering, resulting in a buzzing sound.

Operating this same 120VAC supply in Europe (230VAC) would likely be catastrophic. If the transformer did not saturate and blow the internal fuse first, the voltage on the input to the linear regulation stage would nearly double, likely causing the power supply to overheat and fail.

Linear power supplies are sometimes configurable for different voltage regions. However, because proper configuration is not automatic, the user may unwittingly improperly operate the supply. If, for instance, the supply is configured for 120VAC, but is operated at 230VAC, the user would encounter the catastrophic scenario described above.

Linear Power Supplies and Noise

The transformers in linear power supplies can leak magnetic flux at audio-band frequencies. Guitars and pedals can convert this wayward flux into audio-band noise. Although the output of linear power supplies is typically quiet, their transformers (even toroidal geometries) radiate AC hum that can induce noise into sensitive pedals (e.g. wah-wah pedals).

In light of the problems with linear power supplies mentioned above (i.e. size, inefficiency, heat, etc.), they have largely been replaced with Switched-Mode Power Supplies (SMPS). SMPS are typically much smaller and more efficient than linear supplies.

Rather than using a dissipative pass element to regulate output voltage, a SMPS uses a high voltage transistor switch, which in an ideal SMPS is constantly switching between non-dissipative states. When the switch is on, current passes through the switch but there is no voltage across it. When the switch is turned off, there is voltage across the switch but no current through it.

The high frequency transformers in SMPS operate more efficiently than the low frequency transformers used in linear supplies. This allows more power handling ability in a smaller package.

The added efficiency of these supplies comes at a price. Compared to linear power supplies, SMPS are more complicated to design, especially for ultra-low-noise applications like high dynamic range audio processors, since they have the potential to generate significant amounts of noise.

Designing a Low-Noise SMPS

By carefully identifying sources of noise in SMPS, and through extensive testing and several redesigns, we were able to design a family of SMPS that are as quiet or quieter than linear supplies. To do this, several types and sources of noise needed to be dealt with.

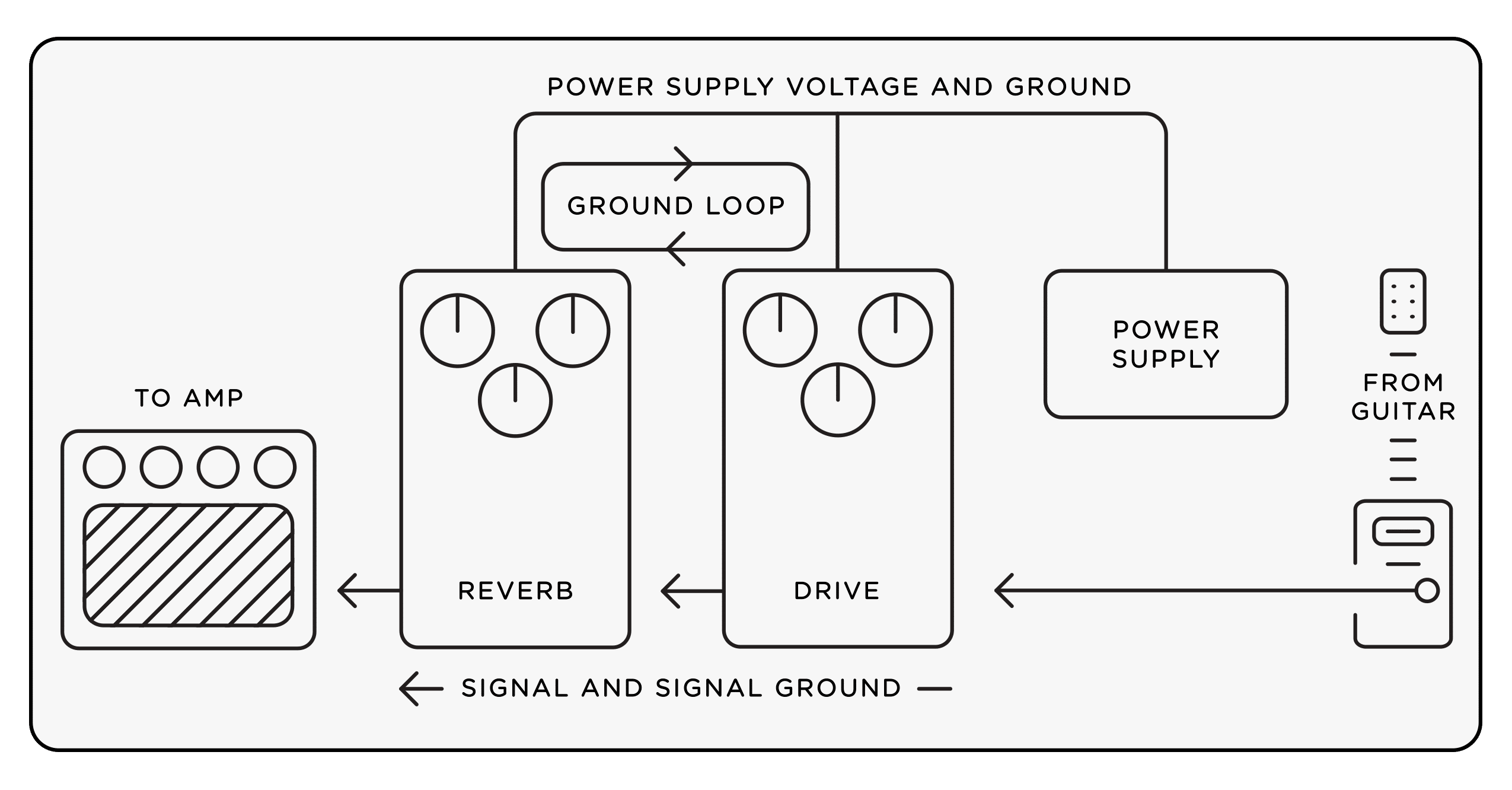

Ground loops exist when multiple paths to ground form a loop. For example, note the ground loop created by powering two guitar pedals from the same power supply:

Figure 3

Figure 3

Exposure to time-varying magnetic fields induces currents into conducting loops. Given the pervasiveness of magnetic fields (stray flux from 50/60 Hz transformers, lighting, etc.), ground loops need to be avoided. Sensitive audio circuits turn induced ground loop current into noise, typically in the form of hum, clicks, or buzz.

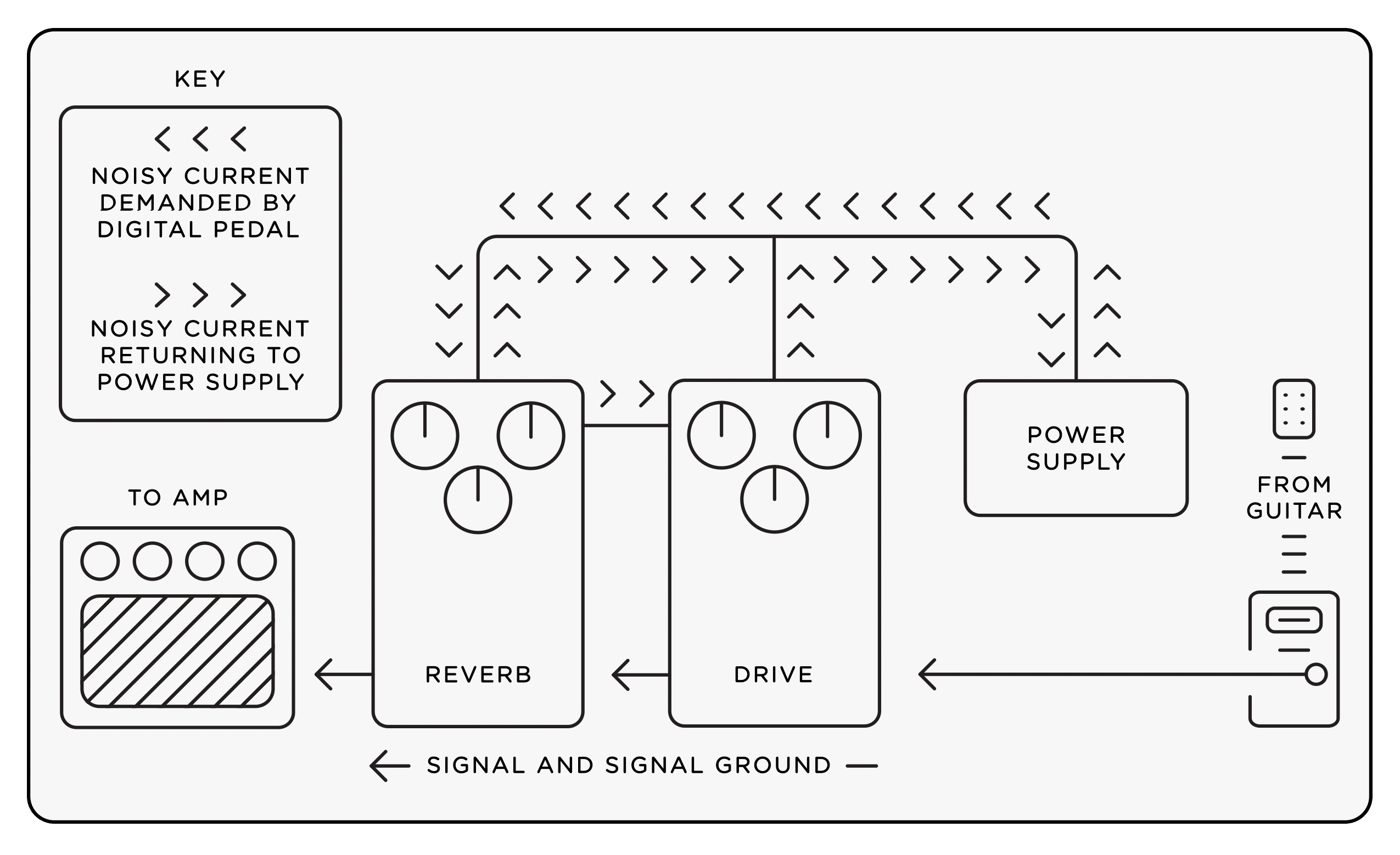

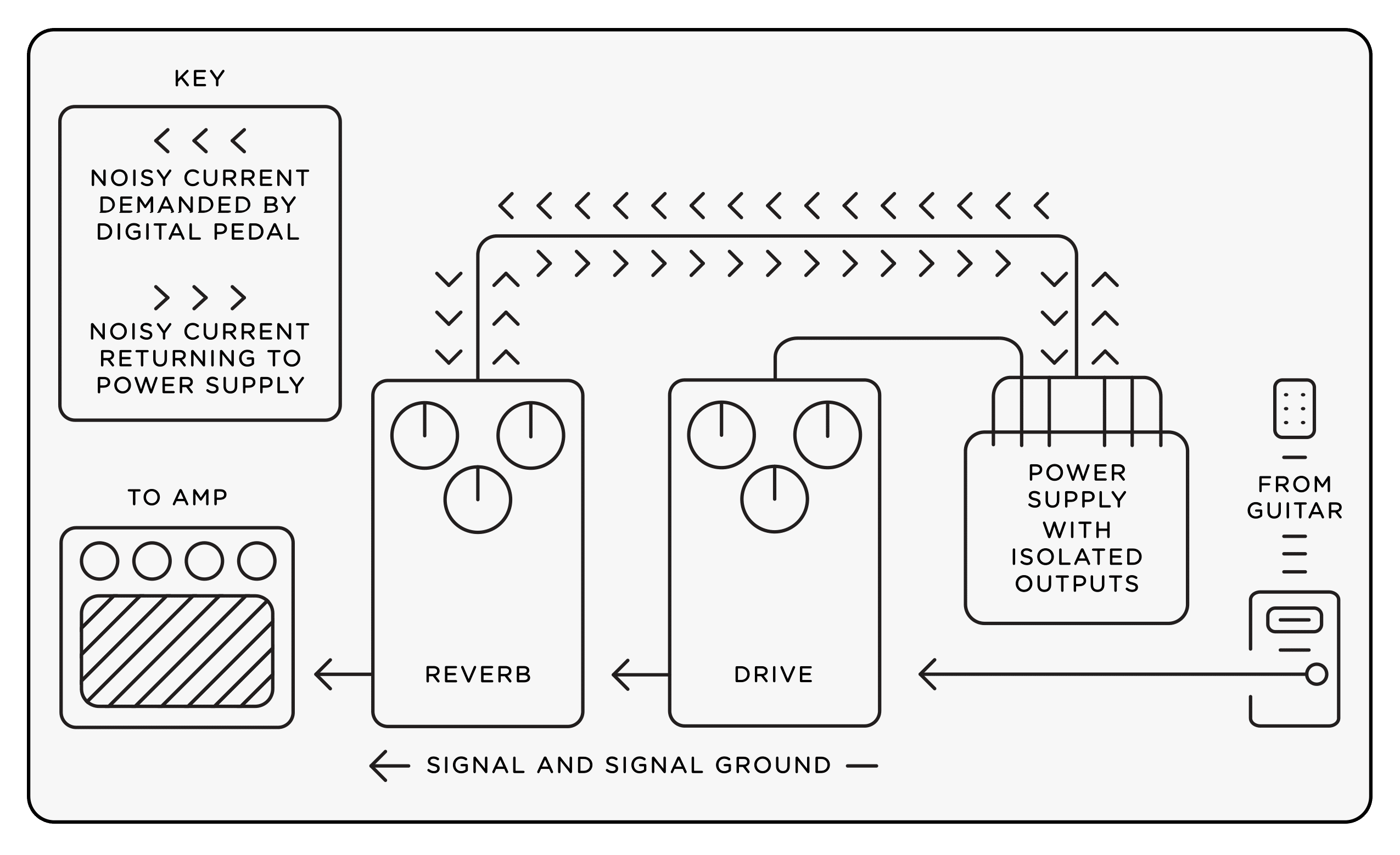

Ground loops can also be a major problem when using power-hungry digital pedals. Due to the dynamic current needs of processors, digital pedals tend to demand current that often varies at audio frequencies. For well designed, properly grounded pedals, this noisy current is isolated to the power supply cable, away from audio circuits and signal grounds. When there are ground loops, however, there are multiple ground paths to the power supply. In this case, some portion of the noisy current will return to the power supply via signal grounds, injecting noise into the audio path through a process known as Common Impedance Coupling.

Figure 4

Figure 4

To avoid the pitfalls described above, Zuma and Ojai employ custom flyback transformers for each output. These transformers electrically isolate the individual outputs, preventing ground loops. Optoisolators optically transmit feedback signals from the secondary side of transformer to the control circuit on the primary side. This allows good regulation without compromising isolation.

In the diagram below, the isolated outputs of the supply prevent the induced noise and common impedance coupling mentioned previously:

Figure 5

Figure 5

In addition to the galvanic isolation provided by the output transformers, care was taken to maximize the the high frequency isolation between outputs. This was achieved using custom common-mode chokes on the individual outputs and minimizing the capacitive coupling between channels.

Differential Noise is an unwanted signal with respect to signal ground, inherent to switched mode power supplies. Unless diligently attended to, it will be present at the supply output.

We take several measures to suppress differential noise. As a first line of defense, we use switching frequencies well above the audio band. Because there are many mechanisms by which ultrasonic frequencies can generate audible noise (e.g. aliasing, nonlinear mixing, etc.), we must ensure that this high frequency ripple does not reach the outputs of our supplies. To do this, we both minimize the ripple voltage at its source and use additional filtering to remove what remains.

To minimize the voltage ripple, we place high capacitance, extremely low impedance capacitors after the flyback transformers. The high capacitance and low impedance minimize the voltage ripple arising from the periodic current into and out of this capacitor. In our isolated output regulators, the small amount of remaining ripple is all but eliminated using a low-pass filter.

Insufficient regulation is another source of differential noise in SMPS. With inadequate regulation, noise present at the input of a regulator propagates to its output. To suppress such noise, we cascade two regulation stages. The first stage converts AC wall voltages (100VAC-240VAC) into 24VDC. For Ojai, this stage takes place in an external adapter. For Zuma, this stage shares a chassis with the output regulators. This first stage largely eliminates the 50/60Hz noise associated with the primary voltage and provides a clean 24VDC supply to distribute to the various output regulators. The output regulators then convert this clean power into ultra-low-noise isolated outputs.

Ojai and Zuma use advanced Pulse Width Modulation (PWM) integrated circuits to control switching. Operating in discontinuous conduction mode allows our current-mode controller to instantaneously compensate for changes in load and primary voltage. Used in conjunction with a precision low-noise error amplifier, we implemented a regulation and frequency compensation scheme that is both extremely quiet and stable under all load conditions. For optimum regulation, the error amplifier measures the voltage both before and after the final filtering stage.

The controller we use also provides a high degree of control over switching frequency. This is necessary for our noise performance. Switched-mode power supplies often modulate their switching frequency at rates within the audio band. The modulation frequency invariably finds its way to the output of the supply. To prevent this noise, we use fixed-frequency switching. Additionally, through very careful layout, we prevent any other signals from modulating the switching frequency.

The high speed switching elements of SMPS can produce common-mode output noise (noise on both the signal conductor and signal ground with respect to earth ground). Many guitar pedals convert this into differential noise that can propagate through the signal chain. In Ojai and Zuma, we deal with this noise by simultaneously minimizing the source of noise and preventing what remains from leaving the supply.

To minimize the generation of noise, we carefully control how quickly the switching components turn on and off. By slowing the rates of change of currents and voltages, we limit the electromagnetic fields that the switching elements generate. Careful circuit board layout also minimizes the amount of noise generated and its ability to couple into other circuitry.

To prevent any noise from reaching the output of the supplies, we placed custom toroidal common-mode chokes on every output. These chokes impede common-mode noise, while leaving differential signals unaffected.

Like the AC step-down transformers of linear supplies, flyback transformers also radiate magnetic fields. We have a couple advantages over low frequency transformers. First, our switching frequency is well above the audio band, so any noise is out of the range of hearing and would be filtered out by well-designed audio equipment. Second, unlike low frequency radiation, conductive shields greatly attenuate high frequency magnetic fields. So where a 60Hz magnetic field would pass right through a thin aluminum chassis, the same chassis would shield a comparable high frequency signal.

Ojai and Zuma were designed from the ground up. Hand-winding our own custom transformers and chokes, we developed a multistage regulation and filtering scheme that automatically converts any wall voltage (100VAC-240VAC) to immaculately clean DC voltage.

Each power supply undergoes a series of audio tests before shipping to customers. In fact, our supplies undergo more rigorous audio testing than most guitar pedals. Each channel is monitored for noise and DC voltage while the output is exposed to a variety of load conditions, using the same Audio Precision audio analyzer that we use to test our pedals.

Born of meticulous attention to design and performance, Ojai and Zuma combine ultra-low-noise performance and high efficiency. They provide clean, abundant power in light-weight, compact packages. Sophisticated and simple to operate, they automatically adapt to any primary voltage between 100VAC and 240VAC. All the touring guitar player needs to do is plug them in and they will work. Most importantly, these supplies provide immaculately clean power so you will hear your guitar, pedals, and amp, not your power supply.

Subscribe to our newsletter to be the first to hear about new Strymon products, artist features, and behind the scenes content!

EDIT: Zuma and Ojai available now! Buy Zuma ($249) | Buy Ojai ($149) We hope 2016 has been great for you so far. It’s been

Rack-mount digital delays of the ’80s ushered in a new era of audio effects. They generated the cleanest delays yet to be heard, but also

Our journey begins with some of the earliest recording studios. The introduction of reel-to-reel tape machines and the creative engineers that used them brought on

9 Responses

Okay cool. When can I buy a Zuma?

Hi Zachary, We will have more of an update as it gets closer to end of September, but will be close to end of September, early October. 🙂 Thanks!

It is because of the incredible quality of design and performance of the three Strymon pedals that I use (Timeline, BigSky & OB.1) and my faith in the geniuses at Strymon to deliver what they promise that prevents me from purchasing an alternative power supply that is currently available.

The wait for this wondrous device has been a level of torture I have not experienced since I was a kid (some 60 years ago) frothing at the bit having to wait to open presents on the day before Christmas.

As a reward for mine and others patience I would request that when the Zuma is released that you include a functional mounting system for the device at the same time.

Not trying to criticize or complain.

More like attempting to whine respectfully!

E W Lambert

Hi EW, We are working on having a PedalTrain mounting bracket for Zuma, which should be ready when Zuma ships. Thanks so much 🙂

Very impressive! The cutting edge.

I love what you have done to the pedal industry. You guys are the BEST !!!

Informative and well=written – thanks you so much!

c

I mean “Thanks so much” or “Thank you very much” – jeez, sloppy fingers…

Just curious as to what makes the Zuma power supply is so light ?